-

October 3, 2025

Injection Blow Molder Reduces Maintenance, Power Consumption

When Michael Durham started at Amcor Rigid Plastics’ injection blow molding (IBM) operation in Youngsville, North Carolina, he encountered a familiar problem that brought to mind an old solution he’d first applied 25 years prior. In a typical IBM setup, up to four temperature controllers can be required to manage mold heating and cooling, posing some inherent challenges. […]

Read More -

September 18, 2025

Ming-Li Precision Introduces PulseCooling Technology to Revolutionize Injection Molding Efficiency and Quality

Taichung, Taiwan – September 2025 – Ming-Li Precision Steel Molds Co., Ltd., a global leader in precision mold design and micro molding solutions, proudly announces the adoption of PulseCooling technology, an advanced pulsed cooling system that represents a significant leap forward in injection molding efficiency, mold temperature control, and product quality. […]

Read More -

September 2, 2025

Injection Molding: Heating & Cooling, Chillers, TCU, PulseCooling™

In ~5 minutes we break down how injection molds are heated and cooled, what chillers do, how thermolators/TCUs manage temperature, and where PulseCooling™ can cut cycle time and improve cosmetics. We’ll hit heat-soak, waterline basics, and practical settings you can apply on press. […]

Read More -

January 12, 2022

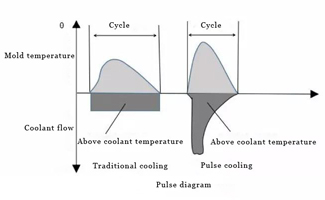

The world's three advanced mold cooling technology

Advanced mold cooling technology, in addition to recent hot-selling water transport technology, there are many other technologies that are unfamiliar to everyone, but has been put into production. The most representative ones are: pulse cooling technology, CO2 gas cooling technology and nano fluid cooling technology. […]

Read More -

September 21, 1998

Taking the heat (away) with pulsed cooling 18996

You wouldn't guess it based on the relatively few molders who actually use it, but pulsed cooling has been around for more than 20 years. However, it's been just in the last few years that technology has made this method of mold temperature control more attractive to molders […]

Read More