PULSECOOLING

THE SMARTER WAY TO CONTROL YOUR PROCESS

THE SMARTER WAY TO CONTROL YOUR PROCESS

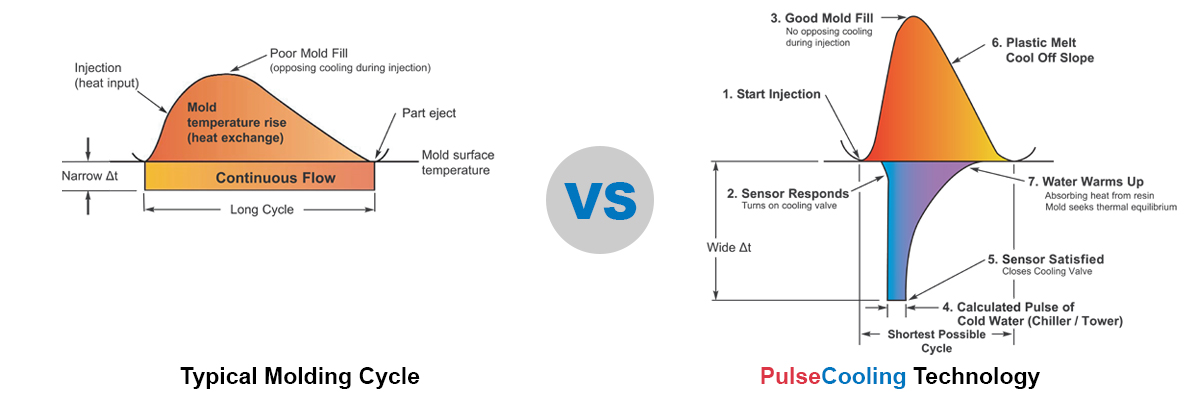

CONVENTIONAL COOLING VS PULSECOOLING TECHNOLOGY

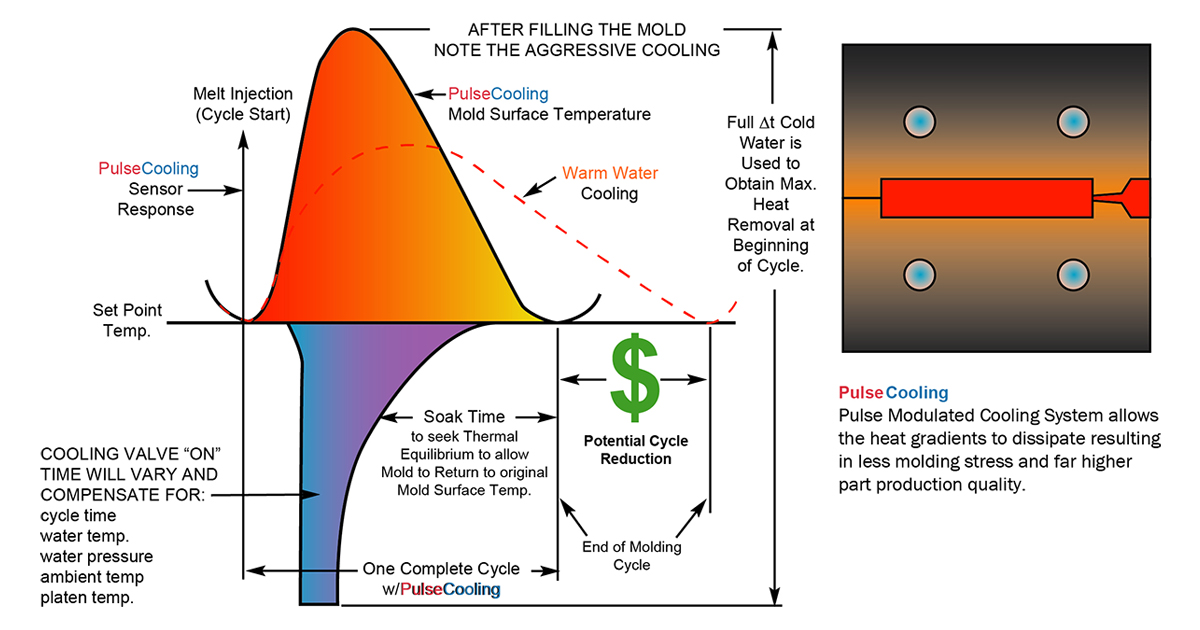

STILL COOLING WITH WARM WATER?? |

PULSECOOLING USES COLD WATER FOR MAXIMUM HEAT TRANSFER |

Continuous Flow Mold Temperature Control Systems |

PulseCooling Technology |

NO DIRECT CONTROL OVER MOLD SURFACE TEMPERATURE |

YOU NOW HAVE CONTROL OVER MOLD SURFACE TEMPERATURE |

|

|

Continuous flow control adjustments are ALWAYS RETROACTIVE in response to visual/dimentional changes in the parts. |

The PulseCooling Technology will save you the trouble by automatically monitoring and controlling your process |

The trend of the Plastic Processing Industry is geared toward higher part complexity, more cavities, thinner walls, larger molds, more difficult to process materials, tighter processing parameters, and better inspection equipment. To obtain the highest performance and meet today's expectations, PulseCooling technology is used to precisely meet the heating and cooling requirements of each molding cycle.

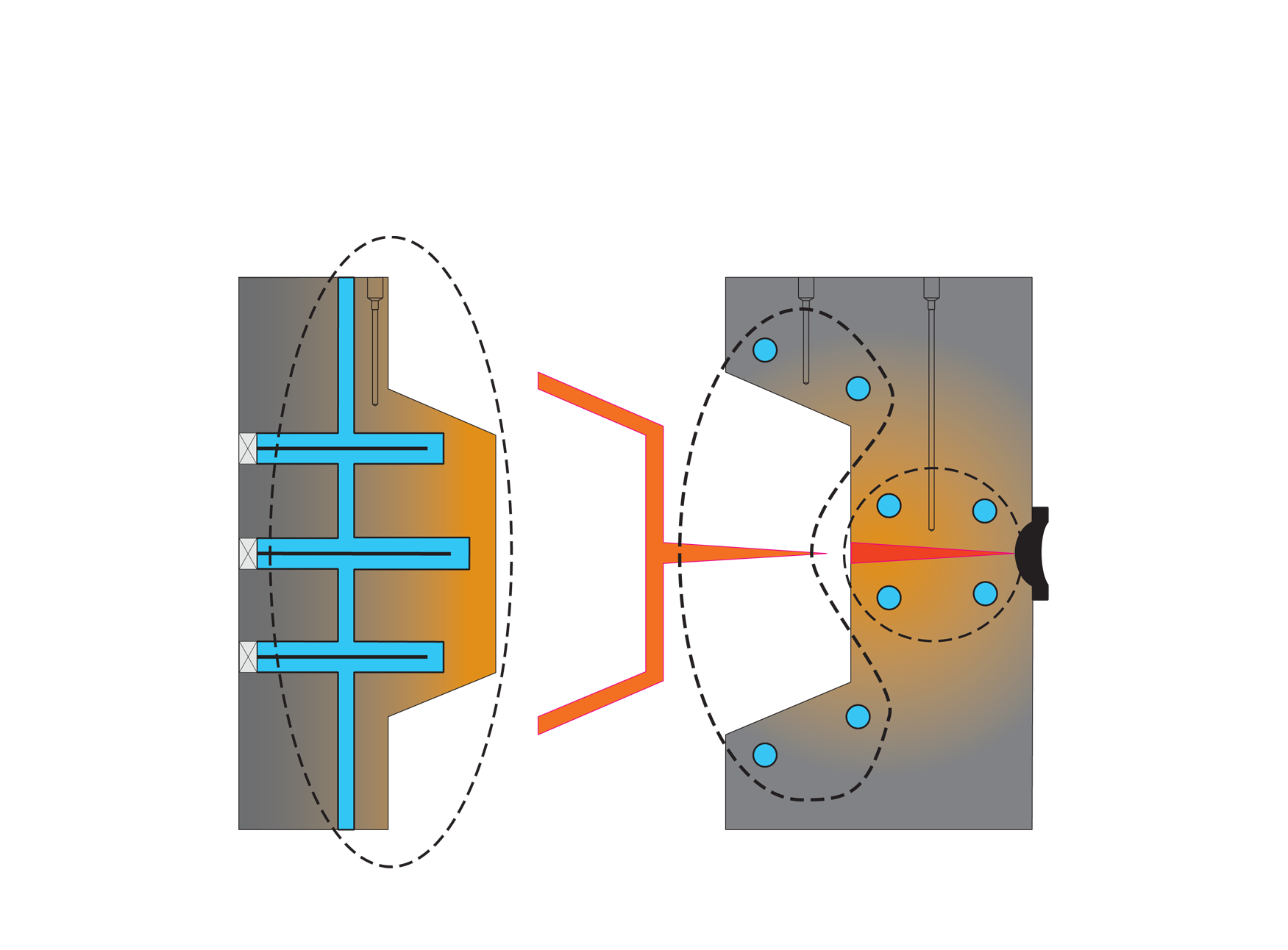

The typical installation requires a temperature sensor inserted in the core and cavity side to "read" the mold surface temperature profile, this provides the PulseCooling controller with vital processing information. The injection melt heat warms the mold surface temperature - not the entire mold.

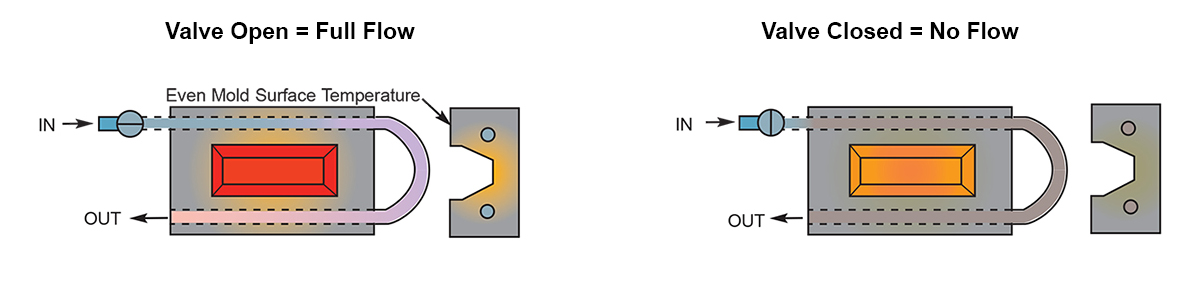

As the mold surface reaches the desired level - the PulseCooling controller processes the information, and commands a fast responding coolant valve to supply a calculated pulse of coolant, (or heating) at maximum flow rate (TURBULENT FLOW) directly from the tower water supply or chiller during each cycle for maximum heat removal.

Beginning of the cycle a calculated pulse of water will match cooling requirement

Maximum Cooling - Full flow - High delta t (cold water)

Turbulent flow for maximum heat removal

Note: minimum temperature rise between

“IN” and “OUT”

No flow during cure time allowing the heat gradients to dissipate providing a more even and predictable environment for the next shot.

Each cooling pulse equals the excess heat from each molding cycle and compensates for cycle time, melt, ambient temperature and cooling pressure (FLOW) change.

When the molding cycle is interrupted - recovery time to the mold surface is quick - since only the mold surface has to rise to set temperature - not the entire mold.

1. Direct control over MOLD SURFACE TEMPERATURE - not just waterline

2. QUICK WARM UP, only the very molding surface reaches temperature, not the entire mold

3. HIGHER PRODUCTION OUTPUT - full flow, turbulent cooling with cold water

4. HIGHER QUALITY PARTS through gradient dissipation during soak period

5. OPTIMIZING OF THE MOLDING CYCLE - continues feed back of mold surface temperature

6. ELIMINATES THERMAL DRIFT (warp, sinks, distortion and inconsistent fill)

7. PRECISION CONTROL OF MOLDING SURFACE TEMPERATURE

Predictable parts through compensation and correction of:

Day and night shift changes, Partial plant shut down - (flow / pressure / temp. changes)

Water Temperature changes (chiller or tower), Cycle changes

Melt heat input variation

Ambient Temperature changes,

Water supply pressure changes,

Back pressure changes.

8. Continuous temperature readout of MOLD SURFACE temperature without cycle interruption

9. INSTANT AUDIO WARNING. Minimum down time.

10. VERY LOW POWER CONSUMPTION (10 WATT/ZONE) approximately $10.00/year

11. MINIMUM WATER CONSUMPTION - Minimum water used for each molding cycle.

12. MINIMIZES COOLING LINE CONTAMINANT BUILD UP - full velocity PulseCooling

13. REDUCES HEAT LOAD to plant cooling system

14. ELIMINATES OVER COOLING during cycle interruption. (rusting)

15. NO FLOOR SPACE REQUIRED - machine mounted - no clutter in back of machine

16. TOTAL ADAPTATION from smallest mold to molds with up to 2" waterlines

17. CONSTANT QUALITY CONTROL - parts are produced within temperature window

18. AUTOMATIC SORTING - Quality control. Relay contact is provided for robotic pick up

19. ELIMINATES MOLD CONDENSATION for low temp. molding (including blow molding)

20. ELIMINATES MOLD DAMAGE caused by thermal growth.(misalignment of mating surfaces)

21. ELIMINATES MOLD JAM-UPS (tapered shut offs due to temperature differences)

22. No heaters, motors or pumps required = LOW MAINTENANCE

23. QUALITY MONITORING SOFTWARE tracking on selected models

24. NETWORK COMMUNICATION available - on selected models