PULSECOOLING: OPTIMIZING EVERY MOLDING CYCLE

FOR HIGH PERFORMANCE

THE SMARTER WAY TO CONTROL YOUR PROCESS

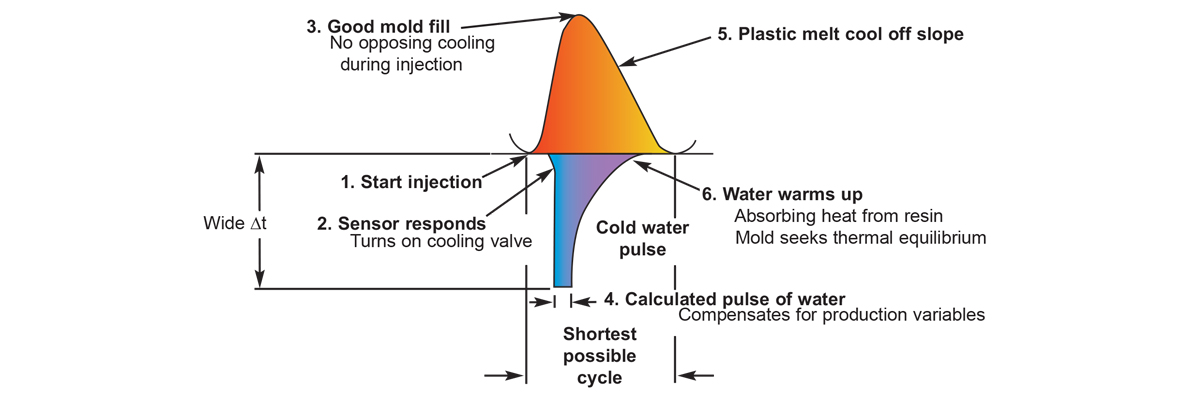

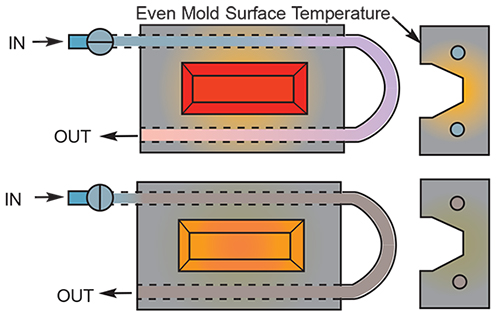

PulseCooling senses the mold temperature and applies a pulse of coolant at maximum flow rate directly from the chiller or cooling tower during each molding cycle for maximum heat removal. Each cooling pulse equals the excess heat from each molding cycle and compensates for cycle time, melt and ambient temperature and coolant pressure changes (flow).

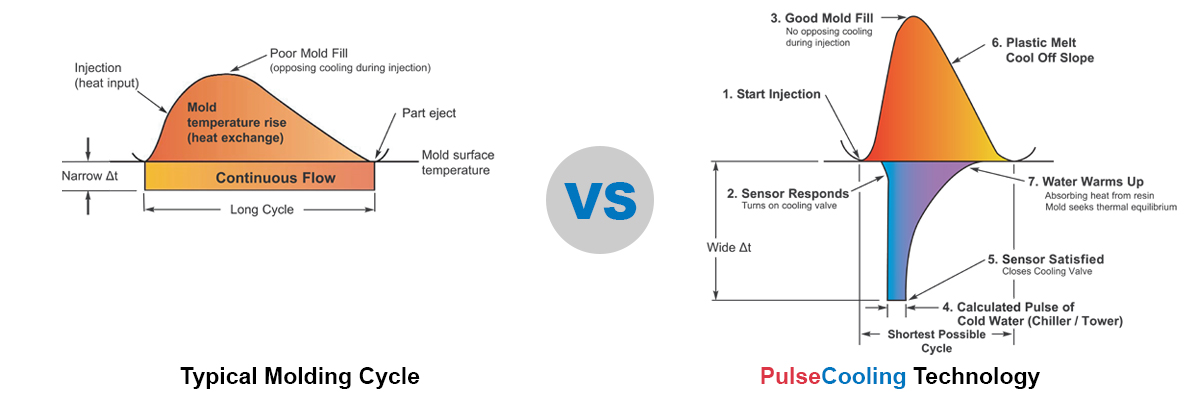

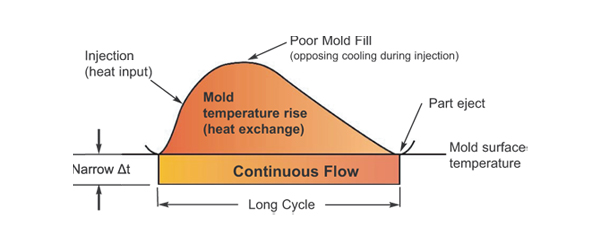

CONVENTIONAL COOLING VS PULSECOOLING TECHNOLOGY